|

Technical Parameters:

Power Supply: AC 220V/50Hz

Applicable Cards:Standard cards with thickness of 0.25-1.5mm

Total Power: 3.0KW

Control Method:PLC+Stepping System

Air Source: 6 kg/cm²

Packaging Film Material:BOPP and other packaging films

Air ConsumptionApproximately 60L/min

Packaging Film Specifications:Folded width of 105mm, inner diameter of 3 inches, and outer diameter less than 450mm for roll material of BOPP packaging film;

film thickness of 0.025mm-0.035mm

Weight:Approximately 700Kg

Production Capacity:3000-4000 pieces/hour

Dimensions:Main unit dimensions L1100×W950×H1700;

Film roll dimensions L700×W600×H1100

Note: Support non-standard customisation of the number of workstations/output/appearance, etc.

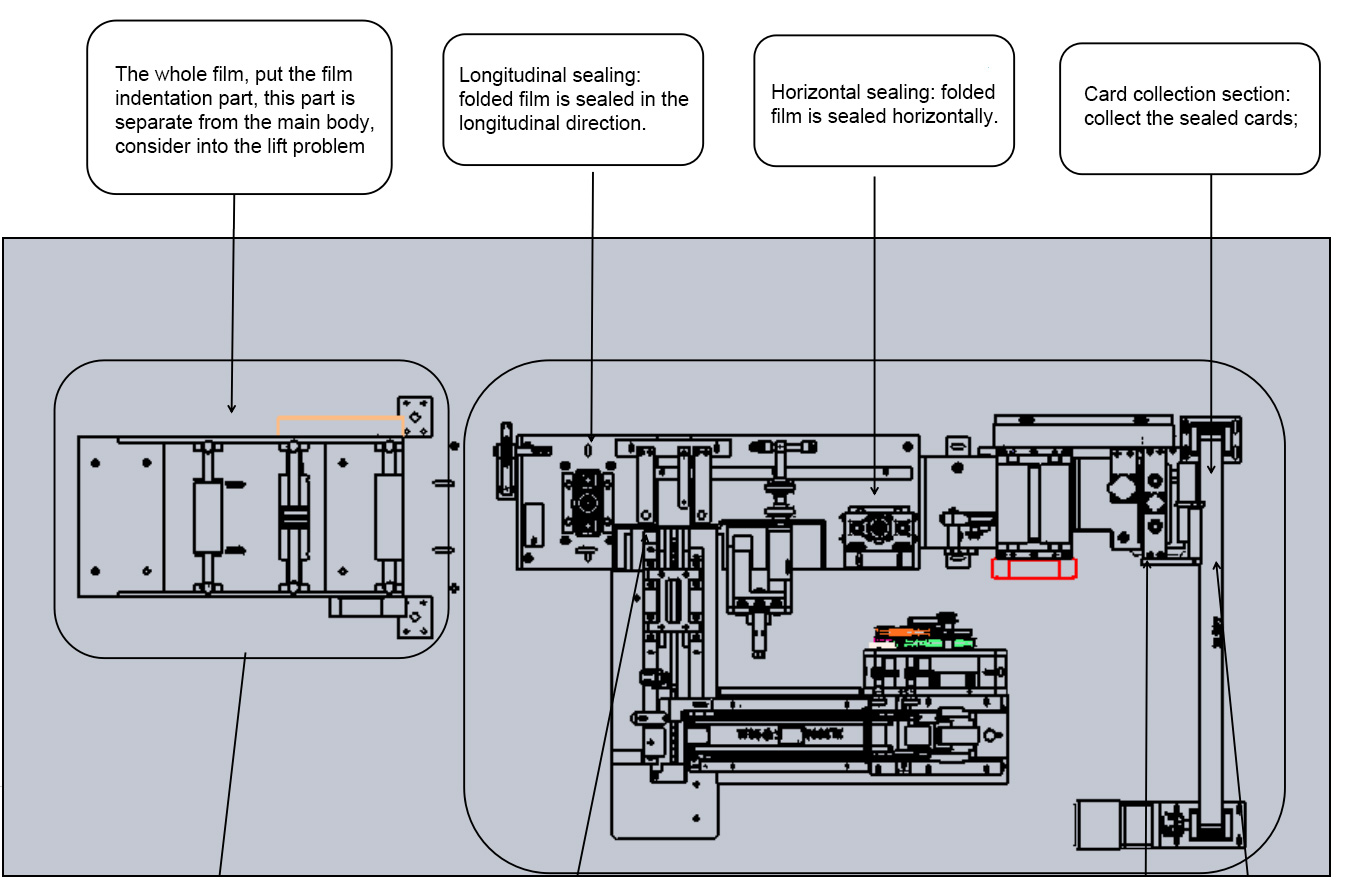

Operating Principle:

Integrates automatic packaging film stepping, packaging, material prevention, card feeding, sealing, and material separation into one system; can operate with a single-track conveyor belt for independent card feeding.

Functional Features:

Independent packaging film feeding mechanism, ensuring stable and secure feeding process, eliminating card damage.

Cards are fed by upper and lower pulling, with a blocking belt card feeding method; this significantly enhances the reliability and stability of the card feeding process.

Uses thermal hot stamping welding, ensuring a stable welding process with clear and aesthetically pleasing weld patterns.

Controlled by PLC programming for fully automatic operation.

Equipped with a high-definition color touch screen for human-machine interface selection, making operation simpler, more convenient, and intuitive.

Professional material collection mechanism, capable of simultaneously handling single-sheet and strip-style material collection (the number of cards can be arbitrarily set).

Some details:

Finesun Precision Machinery Technology (Hong Kong) Co., Ltd

Scan