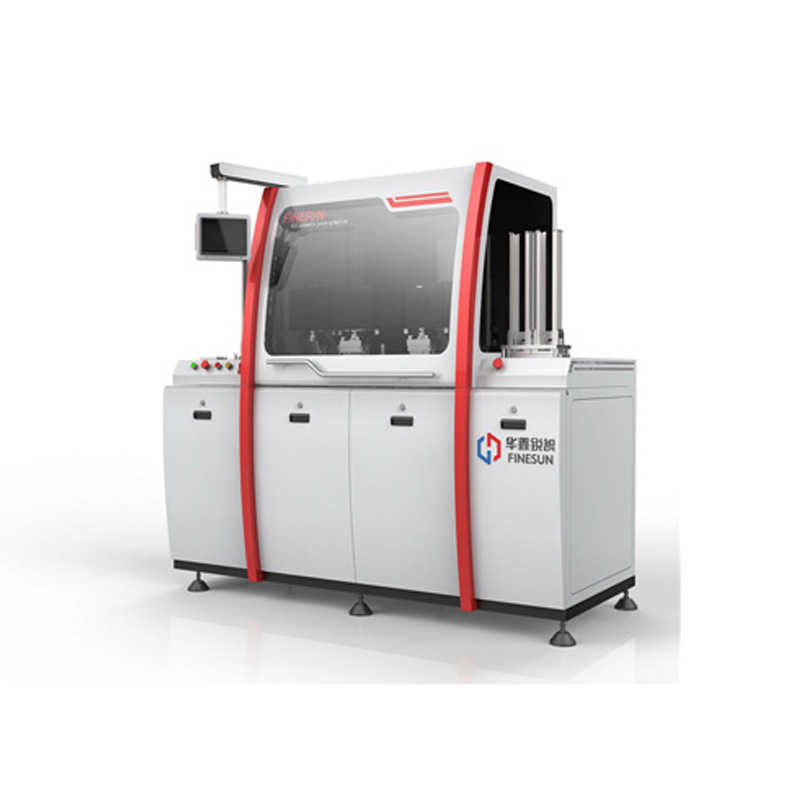

Equipment Introduction:

This machine integrates card orientation testing, conveying, punching, creasing, and card collection into one system. It is automatically controlled by a PLC program and operated via a color touch screen with Chinese and English interfaces. Card feeding and punching/creasing processes are driven by a servo system. The machine features adjustable parameters, high speed, and high precision, making it suitable for punching and creasing line processing of standard SIM cards (2FF, 3FF, and 4FF micro cards).

Functional Features:

The punching mold adopts an advanced structural design, with cutting edges made from imported high-hardness wear-resistant steel, ensuring a longer mold lifespan.

The creasing mold is made from imported high-hardness wear-resistant blades, ensuring better creasing effects for micro cards and easier mold maintenance.

The rational mold structure design allows for easy and convenient replacement. When processing different types of cards, simply changing the mold is sufficient.

A high-power servo motor is used as the cutting power source, providing high parameters, large cutting torque, and high precision.

The modular structural design allows the four workstations to operate simultaneously or independently, offering high efficiency and flexible application.

The machine can operate with either a dual card box or a single card box, conveniently meeting different processing requirements.

Belt-driven card feeding ensures stability, high speed, and card protection. The machine automatically alarms and stops when there is no card in the feed or when the output is full.

PLC program control enables automatic operation, with a color touch screen featuring Chinese and English interfaces. The machine also includes an automatic sampling inspection function, ensuring stable and reliable performance.

Customers can optionally add CCD inspection functionality to check whether the punching and creasing positions of the SIM card are correct.

Main Technical Parameters:

Power Supply: AC 380V, 50Hz

Control Method: PLC program control + servo system

Total Power: 10.0KW

Air Source:6 kg/cm²

Workstations: Four punching stations (number of stations can be customized according to requirements)

Production Capacity:5,000 - 8,000 pieces/hour

Dimensions: L2100mm × W950mm × H1750mm

Finesun Precision Machinery Technology (Hong Kong) Co., Ltd

Scan